Ons outomatiese draaiwielvulmasjiene vir sterrewiele is geskik vir die vul van waterdun tot medium dik produkte, soos vloeibare medisyne, toner, perm-lotion, lugverfrisser, velsorg, ens. Hulle het 'n kompakte opset, 'n klein area beset, 'n mooi voorkoms, maklike aanpassing en 'n wye toepaslikheid, waardeur dit wyd gebruik kan word in die farmaseutiese, plaagdoder, daaglikse chemiese, voedsel- of ander industrieë.

In hierdie reeks word die vul- en afdekaksies aangedryf deur akkurate meganiese transmissie, wat die kwaliteit van die produkte effektief kan verseker. Al die werkstasies, met inbegrip van vulling, dopvoeding, afdak, is rondom een sterwiel toegerus, waardeur sowel die werkruimte as die beheerders benodig word. Die outomatiese en ononderbroke produksiemodus kan u help om die produksievolume wat u benodig, te waarborg. Ons kies goeie materiaal en onderdele om ons masjiene saam te stel. Al die onderdele kom in aanraking met die produkte wat van vlekvrye staal voedsel ingevoer is, en al die pneumatiese en elektriese onderdele is bekende handelsmerkprodukte uit Duitsland, Japan of Taiwan. Dit is die innovasie-ontwerp en die onderdele van goeie gehalte wat verseker dat hierdie reeks masjiene absoluut die leidende posisie in die binnelandse mark van vloeibare verpakking beklee.

Ons roterende sterwielvul- en -knopmasjien pas veral vir die vervaardiging van 'n enkele soort produkte in groot groepe produksie.

Produksievloei:

Vul --- Voer-insetsels --- Druk-insetsels --- Voer-doppe --- Dop

Ontwerp volgens u behoeftes.

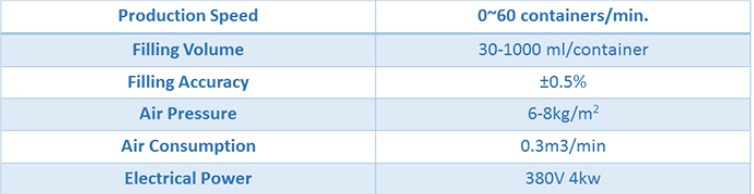

Vernaamste tegniese spesifikasies

Vinnige besonderhede

Tipe: Afdekmasjien, vul- en afdekmasjien

Toestand: nuut

Toepassing: Drank, chemies, voedsel, masjinerie en hardeware, medies, kosmeties, medisyne, chemies, ens.

Aangedrewe tipe: Elektries en pneumaties

Outomatiese graad: outomaties

Spanning: 380V

Krag: 4 kg

Verpakkingstipe: bottels

Verpakkingsmateriaal: glas, metaal, plastiek

Plek van herkoms: Sjanghai, China (vasteland)

Handelsnaam: VKPAK

Afmeting (L * W * H): 1670 * 1350 * 1675

Gewig: 600kg

Sertifisering: ISO9001

Na-verkope diens gelewer: Ingenieurs beskikbaar vir masjinerie in die buiteland

Gehaltebeheerstelsel: ISO9001: 2008

On-site Management System: 5S

An automatic cream filling and capping machine is a highly advanced packaging machine that is specifically designed to package creams and lotions into various types of containers such as jars, bottles. This machine is essential for businesses in the cosmetics industry who want to streamline their packaging process and increase their productivity.

One of the key benefits of an automatic cream filling and capping machine is its ability to fill and cap containers at a high speed. This is achieved through the use of advanced automation technology that allows for fast and accurate filling and capping. In addition, the machine is highly versatile and can handle a wide range of container sizes and shapes, making it ideal for businesses with diverse product lines.

The machine works by first filling the containers with the cream or lotion using a dosing pump that accurately dispenses the required amount of product. The containers are then capped using a capping head that tightly seals the product to ensure freshness and prevent spillage. The capping head can be customized to accommodate different types of caps such as screw caps, flip-top caps, and snap-on caps.

One of the key features of an automatic cream filling and capping machine is its ease of use. The machine is equipped with a user-friendly control panel that allows for easy adjustment of settings such as filling volume, capping torque, and speed. This makes it easy for operators to set up and operate the machine, reducing the risk of errors and improving overall efficiency.

Another important feature of an automatic cream filling and capping machine is its high level of hygiene. The machine is designed to be easy to clean and sanitize, with smooth surfaces and minimal crevices that can trap dirt and bacteria. This is particularly important in the cosmetics industry, where hygiene is essential for ensuring product quality and safety.

In conclusion, an automatic cream filling and capping machine is a valuable investment for businesses in the cosmetics industry. With its advanced automation technology, versatility, ease of use, and high level of hygiene, this machine can help businesses increase their productivity, improve their packaging quality, and stay ahead of the competition. When choosing a cream filling and capping machine, it is important to consider factors such as production capacity, container size and shape, and the type of cream or lotion being packaged.